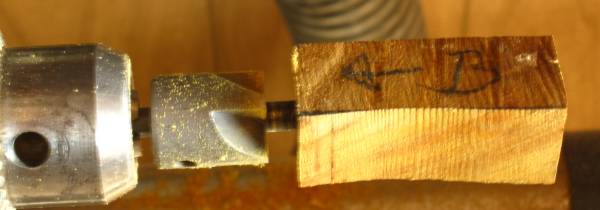

I scrounged around in a drawer and came up with these and was a little baffled at why they were so poorly cut - there were six blanks in this kind of shape. Cutting around bad spots or major band saw problems?

These have a lot of color in them so maybe that was it.

These were a bit of a challenge to drill, given the way they were cut. And speaking of cut, these look at least partially cross cut so this may more time consuming than I originally planned.

Spend a some extra time and trim the blanks with the band saw as close to the brass as you can get and then add some thin CA glue to the ends. The reason for this is that tear-out can be a major problem with cross cut blanks. CA glue helps stabilize the ends of the blanks. You want to keep milling to a minimum.

Use a sharp pen mill and while you are at it, ensure your turning tool of choice is very sharp too.

Take that extra step and add some more CA glue to the ends of the blanks. Let it dry and then hand-mill the ends lightly - just enough to remove any excess glue.

Something useful to remember:

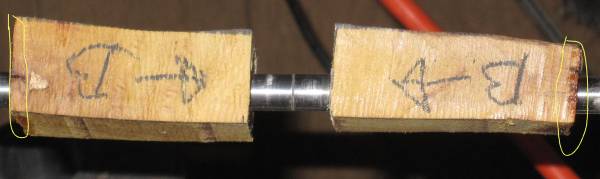

When you cut a blank in half, work from the center out when drilling and cutting the blanks down to size.

That first cut which divides the blank in two should be as close to perpendicular the the blank as possible.

Install the brass tubes as flush as possible to the inside -><-.

Excess wood should be cut from the outside ends of the blank <--> (circled in yellow).

This is particularly important if you have highly figured blanks and you wish to match up the patterns of the top and bottom blanks when assembling the pen.

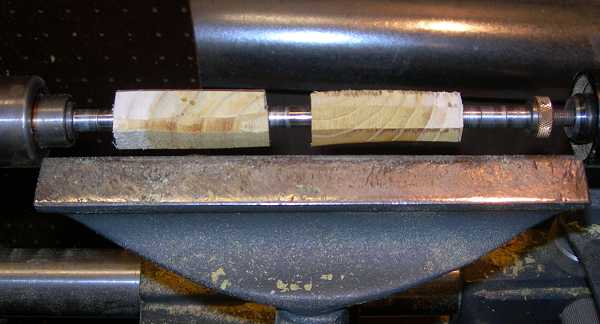

Yup, these were partially cross cut. If you feel the tool dulling at all, resharpen it. If you don't, you will more than likely catch the tool on the grain and rip part of the blank out. Been there, done that several times.

For cross cut pieces, it is better to leave them a bit over sized and sand down to the final dimensions. One catch and the blank is history. Apply one more coat of CA glue and let dry. I don't use accellerant. Sand to at least 400 grit.

At this point I remove the bushings and slide the blanks over a bit of string to keep them in place.

Touch up the ends with a pen mill, removing excess CA glue.

Lightly sand to 600 grit, rounding the sharp corners of the ends of the blanks. This extra step can make for a much nicer end product.

EEE takes you to somewhere around 1500 - 2000 grit, which really can bring out the shine in cross cut woods.

I start working the EEE in, and then add a drop of thin CA glue to the mix.

A coat of Mylands Friction Polish finishes the blank.

Don't forget to mill those ends one more time.

A couple swipes with a chamfering tool make pen assembly much easier.

It's always a good idea to lay out all the pieces. Pencils are harder to assemble so I will do that first.

Press the pencil cap and clip in first.

Press the center band into the pen top. Now comes the fun part.

The easiest step to screw up is this one. Keep a close eye while pressing, ensuring both parts stay parallel to each other.

If it starts looking like this....stop, adjust and continue.

This looks much better. Any kind of bow and the pencil ratcheting mechanism will not ratchet correctly.

Not bad. Now for the pen.

An easy step to forget is failing to take a width measurement off your first completed piece.

This is supposed to be a matching set so it would be nice to keep pencil and pen dimensions relatively the same.

The pen blank is easier to turn because while there is some cross cutting in there, it is not as severe.

Turned our rather well if I do say so.

One Hedge Apple pen and pencil set from an 80+ year old tree taken down in Olathe, Kansas in the summer of 2008 and turned May of 2009.

A few more notes on cross cut woods:

Turn your four sided blank into an eight sided one before turning if the wood is quite hard.

It saves time and wear and tear on tools.

Consider sanding down to the final dimensions rather than cutting. It only takes a few more minutes and will prevent blowing out the blank ends.

Take some extra time sanding, going to a finer grit than you would normally. The light really refracts off this style of pen, which is my personal favorite.

If you are bored one day, turn a flat, cross cut pen and then turn a cross cut pen similar in shape to the one shown here.

Sand and polish them the same and then take them out under a bright light. There is a noticeable difference.

Keep that tool sharp. If it shows signs of dulling, resharpen immediately. Not so important when turning blanks cut with the grain, but dull tool + cross cut blank = tear out.