Turning a Natural Edge Red Mallee

Bowl

I bought a Red Mallee burl several years ago with the intent of saving

it until I got good enough with a lathe and lathe

tools not to trash out the burl or the tools..

I figured I would reserve the burl until a special occasion presented

itself. One did - my brother's wedding.

This is one hard piece of burl.

This is the back side. Still looks to me like a turtle shell.

The first order of business is to mount it and this clearly, is not

going to work.

My favorite tool - the chain saw blade attached to a grinder does the

trick.

Takes about five minutes go make a flat surface.

I tried mounting the faceplate and promptly broke two screws off in

pre-drilled holes.

This stuff is hard. I went to the local hardware store and

bought sturdier screws and

a new drill bit.

Drilling at even the slowest speed causes the bit to heat up and the

wood to burn.

This is going to be fun.

Even

after drilling, three out of the six screws broke. I wonder

if this is superior Chinese craftsmanship.

Anyway, I finally got the burl mounted. I am using a speed

reducer, turning at about 100 rpm.

A quick way to get this round is with a little assistance from my

favorite tool:

My aim here is to get the burl round and to find a center.

A view from the top.

I am finally finding the bowl bottom. My intent is

to attach a sacrificial block to the bottom so I don't lose too

much bowl depth. There isn't much to start with anyway.

The bowl is now reasonably round.

I decided to depart a bit from the norm and glue the block on to the

bowl while still mounted

on the lathe. I figured that when it dried, I would turn the

block down to exactly the same diameter

as the face plate and be able to transition from outside to

inside without much material loss.

Looks like it is glued on pretty well. Now it's time to

switch positions.

Switching positions from back to front wasn't much of a problem but

getting three broken-off screws

out of the center is.

That is, until I use my handy dandy chainsaw attachment to gouge in

near the screws and then extract

them with vise grips.

I decided this time to use a forestner bit to drill down to the correct

depth, which is 1/2" thickness to start.

I was making really good progress until the bowl flew off the lathe,

bashed into a shelf and landed on the floor.

My first thought was, 'Oh, #$%@ - I trashed this one big time.

And then after looking it over, it looked like the burl was so hard it

literally bounced off the floor and landed

intact. The advantages of hard wood.

Three days later, the glue job appears to be holding. Away I

go again.

I resort to my parting tool / gouge technique and

make rapid progress

One thing to consider when turning a really hard, natural edge bowl, is

that those natural edges

are pretty sharp. I upped the lathe speed to 500 rpm and got

in the way of the rim.

Gloves are a really good idea.

One bandage and an hour or so later, the bowl is pretty much turned to

where I want it to be.

There are numerous fissures, cracks etc., so I use medium viscosity CA

glue and sawdust to get the outside

looking reasonably intact.

Lots of problem areas inside the bowl too. There are a lot of

problem areas so I mix about a teaspoon

of CA glue with sawdust, forming a pretty good wood filler.

Sawdust and super glue - two staples of the wood turner. The

bowl sets for several days.

I could go into the grief endured in trying to get a decent finish but

I think it can be described in

one sentence: "Do Not USE Spray Finishes in Dusty Rooms".

The final finish was two coats True Oil and three coats Clear Urethane

brushed on.

After describing my woes with this particular project a female

acquaintance asked me why I didn't take a class

or two on this stuff and take some of the guess work and headache out

of the process.

My response was, 'Yes, that makes total sense but you have to

understand, this is a guy thing. '

Need I say more?

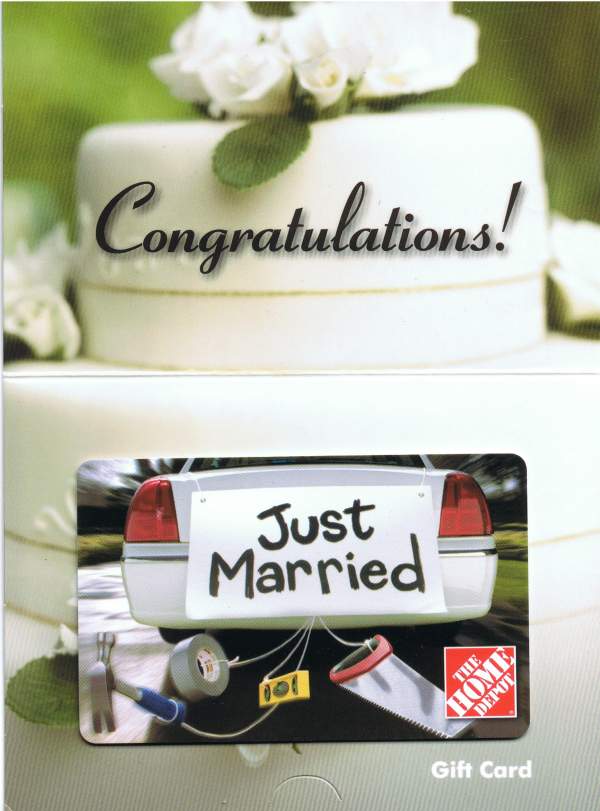

At any rate, Congrats Matt & Ann.

We hope you enjoy many happy years of home improvement and if you need

a little help getting

started, this may assist:

Dan & Debbie