I found out from my last go-round with acrylester, that if you get the speed high enough and ensure the back of the tool lays against the blank, the plastic softens from the heat and comes off in ribbons, rather than chips.

I am starting to think too, that this is not entirely my fault. The tail stock on this lathe sports a live center and one thing I have noticed is that I tend to pick up a little vibration at that end from time to time, as in this case. What I've been doing is swapping the blanks to the head stock end to do the detail work. It does seem to help in that not so many blanks blow up.

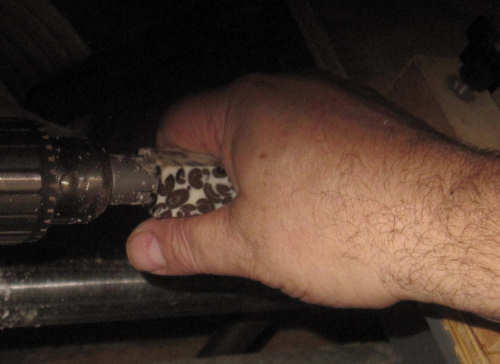

I did a light hand milling and tore out a coffee bean. Fire up the lathe and lightly mill the ends one more time.

Coffee Bean and Cream Pen Blank Specific Notes:

1. Turning this kind of pattern makes it appear as if there are hills and valleys when turning. It played havoc with my depth perception so I ended up feeling where I was by running my finger across the blank whilst turning to get a better perspective.

2. The coffee beans themselves many times appeared to have small cracks in the center, where the acrylester did not fully melt in. As I got closer to the finish, I stopped several times and coated the beans with thin CA glue in order to prevent them from cracking out.

3. The instructions were right in that you do need a light touch. The coffee bean blanks will turn down very fast with a sharp tool but you need to ease up when you get close. If you have ever worked with spalted woods, you know what happens if you are not paying attention and hit a pithy area. What happens is you can drive your tool much further into the piece than you had planned, and this happens in a micro-second. Think of the coffee beans as pithy areas and treat them as such, This includes their reinforcement with CA glue.

4. The instructions also said that with a true CA glue finish, you can no longer smell the coffee in the beans. I don't know if that is a fact or not, but I do know that using the hybrid finish I like, there is no doubting the pen is constructed in part with rather pungent coffee beans.

5. I noticed in spots where the acrylester was getting a little thin, you could see brass if you held the pen up to a light. Next time I would coat the brass tubes with either a black magic marker, or white - if they make such a thing.

Have fun!