(By the way, some of these on line vendors have a very interesting on line ordering flaw).

read some instructions or dive right in?

Dive right in, of course..........it's a guy thing.

This was purchased from Woodturningz as discontinued stock. The price was right.

If you were tight on material, this would be a problem. There is plenty of material here so this is not a concern.

If it was a concern, a closer examination of the instructions says not to drill all the way through and use a band saw to cut off the end.

This looks simple and straight forward, right?

I wasn't using that much pressure but the chips flying off the blank are making this kind of pain in the @$$.

One advantage with acrylic pen blanks using this kind of design is you don't have to worry about not having a matched pen.

It looks all the same.

Just need to turn the end down flush....

Let's see how that works.

Then it dawns on me. How does plastic, acrylester and other synthetics of this sort react to speed and friction?

It softens.

So, how about double the speed to say, 1750 rpm? Couldn't do any worse except that the blank might really blow up.

Best to ensure the tool is sharp.

Not only does the blank turn down rapidly but the chips have gone away, turning into thin plastiky acrylester flakes.

The blank on the right was turned using the slower speeds and chipping is clearly visible. The blank on the left looks quite clean.

What works very well is to rest the bottom of the tool against the blank and lean the tool into the blank. The tool heats up the acrylic blank a bit and with a little practice, the blank takes on a shine while turning.

I started with the thin CA glue but switched over to the thicker stuff to fill in deeper holes. I let it dry naturally.

I then re-sanded and finished the pen off with my custom EEE / CA glue finish.

2012 Update on Hole Filling

The following works well for these types of holes:

Spray the hole with accelerant. Let it sit for 10 seconds or so.

Use a medium viscosity CA glue and apply one drop. The accelerant keeps the drop in place and hardens it quickly.

This method does not turn the CA glue white.

If after a few minutes it the dot of CA glue still feels tacky, hit it with more accelerant.

Sand off the excess.

2012 Useful Tidbit for Blown Up Blanks

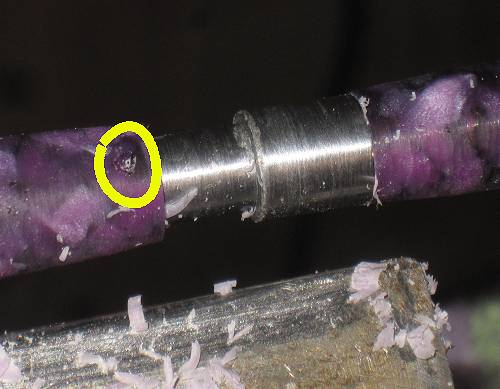

Don't you just hate it when this happens? Sometimes these tubes are non-standard lengths and it can be a pain to find a new one.

Reuse the brass tube! Only takes a minute or so using a parting tool to break up the plastic.

It's already sanded, roughed up and ready to go. And....... you get to see what kind of glue job you really did.

From the top down:

Molten Metal - Acrylester

Doodles - Plastic

Gold and Black - Acrylester

Doodles - Plastic

Bananas and Grapes - Acrylester

Red Russet - Acrylester

Area 51 Plastic

Closing Comments:

Choosing the correct type of blank:

Choosing the type of acrylester or plastic pen blank depends on the pen size.

If you are turning a 7mm pen, choose a solid colored blank and not a opaque one or you frequently end up

seeing the brass tube through the plastic, particularly at the narrowest ends of the pens. as shown in the above example

Solid blanks like these work much better for 7mm pens.

If you want to use a opaque blank anyway, coloring the brass tube with a magic marker that complements the blank can really help.

8mm and on up, the opaque blanks work well enough.

Sanding:

I didn't use Micro mesh on any of these pens save one.

I saw no difference between a EEE / CA glue finish and a Micro mesh finish, other than Micro mesh took longer.

Don't forget to turn the speed down or you can end up melting your sand paper into the plastic pen blank.

Cracks:

Some of those Acrylester pen blanks had longitudinal cracks not visible until after initial turning.

Stop and check for cracks several times whilst turning the blank down to size.

I called the supplier about this and he said this was an occasional problem and he would send replacements. He did.

The plastic pen blanks had no hidden cracks.

The Acrylester did.

I did try repairing a couple of those cracks but they seemed to chase down to the end, which was an exercise in futility.

Turning:

Turning downhill works better than the reverse.

Speed:

Crank it up. Acrylester seems to turn well at 1750 rpm. Acrylic and Plactic I get better results at 1150 rpm.

Acrylester pen blanks throw out chips while getting them down to round. Plastic or Acrylic - not so much.

These chips will turn to soft plastic flakes if the turning speed is high enough, and are much more pleasant to work with.

Conclusion:

An interesting diversion but I think I prefer the real stuff.

But...........

a few more like this and I might just change my mind.

Here are a couple more:

I didn't blow up any blanks with these. A sharp tool, high rates of speed and keeping the tool against the acrylic blank works wonders.

No divots at all!

2-2-2012

Looking for a litte more info on plastic and acrylester pens?

Here is a link for turning the Duchess Pen, with a bit more information on CA glue finishes and turning acrylester.

1-4-2011

Wade from Albuquerque, New Mexico was kind enough to send these along:

Orange Acrylic

White Acrylic

Laminate

Comment: Very nice looking pens. I haven't tried a laminate myself and will have to do that some day.

If you would like to see more of Wade's Pens:

"I have my pens posted on my facebook page if you want to look at them. just search Wade McCloskey in Albuquerque and you should be able to find me. I will attach acouple of pictures of pens I have turned that are on that are there."